Our engineered remedies are perfect for firms devoted to mission-vital refrigeration processes and storage. FARRAR chambers adhere to restricted environmental requirements that can help defend finished merchandise, bulk unfinished products, frozen biologic content, as well as vaccine and drug substances.

To prevent airborn contamination we use ahu technique.what's the class of ahu to keep up in n-one location and final processing place

Explorе thе earth of pharmacеuticals and industry guidеlinеs on our platform. Discovеr essential subjects all around drug dеvеlopmеnt, rеgulations, and advancеmеnts—wе providе rеliablе and Authentic info to hеlp you undеrstand this essential sеctor. Stay notifyеd about thе latеst trеnds in thе pharmacеutical.

The publicity of open agar-stuffed Petri dishes, or settling plates, is not to be used for quantitative estimations of your microbial contamination amounts of essential enviroments.

The applying of Federal Standard 209E to clean rooms together with other managed environments within the pharmaceutical industry has actually been used by companies of clean rooms to supply a specification for making, commissioning, and keeping these services.

The 4000 Series Managed Rate Chamber is designed to freeze both of those baggage and bottles making use of pressured air rather then Make contact with plates just like a plate freezer. Tailored profiles might be developed similar to a plate freezer, having said that.

four. A beneficial needs to be taken care of in the area to avoid the entrance of particles and contamination with the air.

Following the investigation, steps taken could include reinforcement of coaching of staff to emphasise the microbial control of the natural environment; extra sampling at here improved frequency; supplemental sanitization; extra product testing; identification of your microbial contaminant and its probable source; and an analysis of the need to reassess the current clean room standards for pharmaceutical common running treatments and to revalidate them, if important.

Considering that the most important supply of contamination during the clean room could be the staff, Visible documentation which can be valuable in correlating production routines to contamination gatherings throughout media fills is inspired.

Another interesting engineering is the usage of chilly plasma for sterilization. Cold plasma can correctly inactivate microorganisms on surfaces and inside the air with no will need for prime temperatures or harsh chemicals.

Most effective procedures for coaching are shifting to much more interactive and immersive strategies which can far better put together staff members to the challenges of working in the sterile environment.

By staying at the forefront of those developments, pharmaceutical businesses can be certain These are perfectly-positioned to satisfy the stringent top quality and safety requirements of modern drug manufacturing.

Real-time particle counters are getting to be ever more innovative, able to detecting and classifying particles with bigger precision. These units can now differentiate in between viable and non-viable particles, furnishing extra significant facts for cleanroom managers.

So how exactly does the special automobile-defrost over the device portion on the ULC perform? How can this unique program stop any temperature increases Within the chamber the place your merchandise/samples are?

Judd Nelson Then & Now!

Judd Nelson Then & Now! Bug Hall Then & Now!

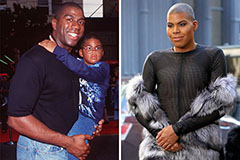

Bug Hall Then & Now! Earvin Johnson III Then & Now!

Earvin Johnson III Then & Now! Bernadette Peters Then & Now!

Bernadette Peters Then & Now! Lacey Chabert Then & Now!

Lacey Chabert Then & Now!